Working principle of ordinary air source heat pump.

In nature, water always flows from high to low, and heat is always transferred from high temperature to low temperature. But people can use water pumps to lift water from low to high, so as to realize the flow of water from low to high. Heat pumps can also transfer heat from low temperature to high temperature, it is essentially a heat lifting device. Its role is to absorb heat from the surrounding environment and transfer it to the heated object. The mechanical device that can convert heat from low temperature to high temperature is called “heat pump”.

Air source heat pump = heating in winter + cooling in summer (meeting the requirements of both winter and summer working conditions) other heating equipment can only be used for heating in winter, and air conditioning equipment only be installed for cooling in summer.

The air source heat pump uses 1 part of electricity, and at the same time obtains more than 2 parts of free air energy from the outdoor air, and can produce more than 3 parts of heat energy, which is highly efficient and environmentally friendly.

The four major components of air source heat pumps include evaporator, compressor, condenser and expansion valve. By letting the “refrigerant” (commonly R22, R410A, R417A, R407C etc.) continuously complete the thermal cycle of evaporation (absorb heat from the environment) → compression → condensation (release heat) → throttling → reevaporation, the heat in the environment is transferred Into the medium (water).

When the air source heat pump is working, it first inputs 1 part of electric energy to drive the compressor to do work (this part of the electric energy will eventually be converted into heat energy), and then absorb a large amount of heat energy from the outside environment temperature, and through the refrigerant circulation system in the condenser to release the heating. As to “law of conservation of energy” , that the 1 unit of electrical energy input to the compressor can always be converted into 1 unit of heat energy, and the large amount of heat energy absorbed from the external environment becomes an additional income. In other words, the main force that really heats water is not the input of electrical energy, but the free “heat” in the air.

2. EVI heat pump jet enthalpy increase technology.

There were a lot of problems with the ordinary air source heat pump, such as too noisy operation, too large unit volume, and low heating efficiency at low temperatures. The heating efficiency at low temperatures was not high, which really affected the performance of the product. Many manufacturers also have begun to tackle this difficult problem, such as the “jet enthalpy increase” program.

Strictly speaking, the so-called “air jet enthalpy increase” technology is based on a complete system, which is composed of special components such as air jet enthalpy increase compressor, hot water heat exchanger, evaporator and so on. But the compressor plays a central role in it, so what is a jet compressor?

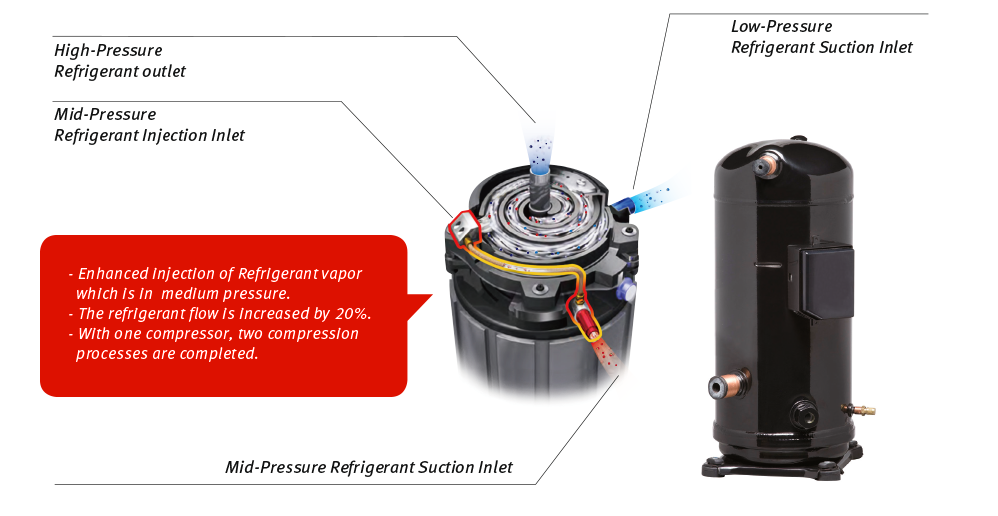

The picture below is a dedicated compressor with “jet-enhancing enthalpy” technology. This compressor adds an additional steam injection port. The compressor receives the energy transferred from the evaporator from the suction port, and receives the steam supplemented from the other end of the pipe from the steam injection port. The steam is used for the continuous circulation in the cooling pipeline. Refrigerant (refrigerant). The essential meaning of this is to use the entry of steam to divide the original one-stage compression process into a quasi-two-stage compression process.

To illustrate more clearly, we can analyze this process step by step:

Step 1: the compressor receives the heat A absorbed by the evaporator from the air and compresses it;

Step 2: Open the air injection loop for increasing enthalpy, and the steam is passed into the compressor;

Step 3: The part of energy A being compressed by the compressor is mixed with the incoming steam. This process will continue until the working chamber of the compressor is separated from the supplementary air port. At this time, the steam and energy A are fully mixed and become a new stream energy B;

Step 4: After the compressor working chamber is separated from the air supply port, the energy B is compressed by “secondary”, and finally the energy B enters the condenser to exchange heat with water.

Linsam EVI air source heat pump adopts Copeland special produce EVI compressor, highly improved the low temp heat pump working performance, at low temperature it also can quickly heating the house.